Many of us take poison prevention for granted. From household cleaning supplies to personal care products and prescription medication, many items exist in our own homes that are dangerous when used improperly.

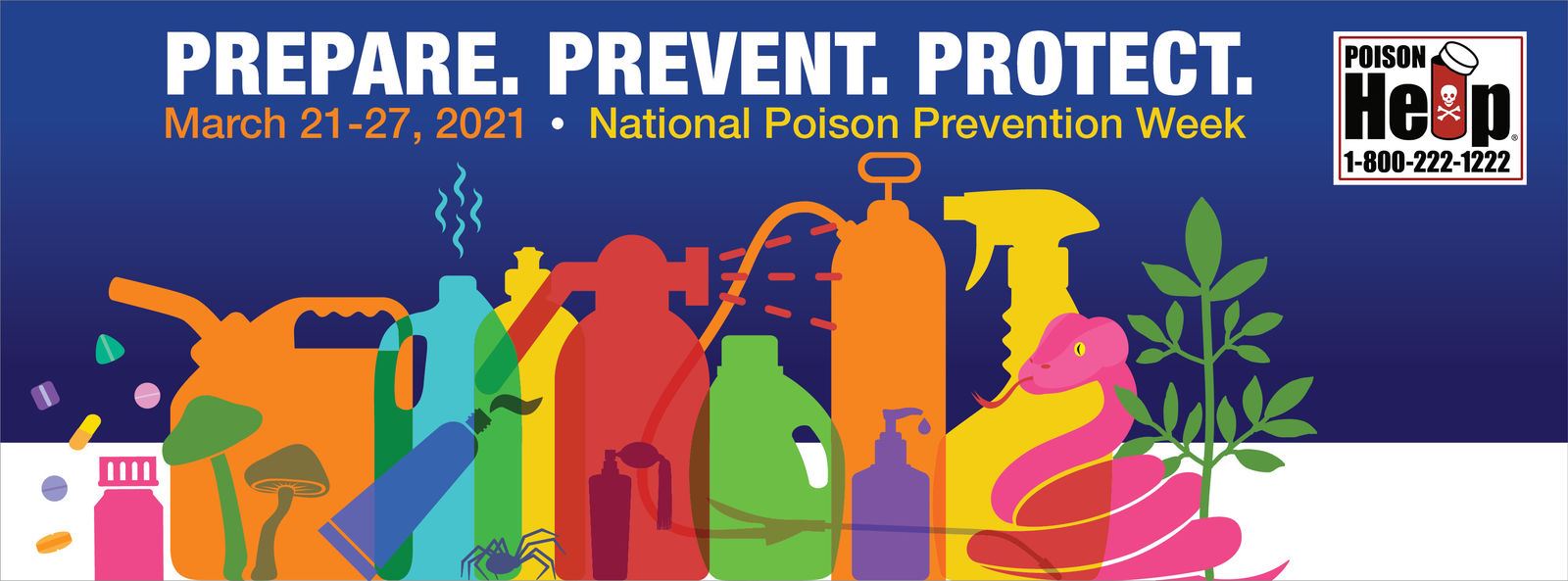

National Poison Prevention Week (NPPW), is nationally designed to highlight the dangers of poisonings and how to prevent them. However, every day people can and do prevent poisonings. We believe that safety is a partnership between those who make safe packages and design warning labels, and the consumer.

- The National Poison Prevention council encourages you to have the poison control

number handy: 1-800-222-1222 - Remember, safety packages are child RESISTANT, not child proof

- Keep hazardous substances up-and-away and out of site

Click here to read the full Presidential Proclamation about NPPW.

Since March 21st begins National Poison Prevention Week, now is a great time to shed light on the issue of accidental poisoning. In 2019 alone, U.S. poison control centers provided telephone guidance for over 2.1 million human poison exposure incidents. Nearly 4 percent of children under the age of six experienced poison exposure that year. This is not just about handling obviously poisonous materials either – practically anything can be poisonous if used in the wrong way, at the wrong dose, or by the wrong person.

One way to help reduce these dangerous statistics is through better packaging and closure design. When we think of packaging, we often think about it in terms of what looks nice, what is easy to use, and what can help keep our products intact. But packaging also plays a very crucial role in poison prevention.

Through proper packaging and closure design, you can:

- Better child proof products

- Prevent accidental exposure to poisonous substances

- Ensure packaging stays structurally sound for longer, eliminating any breakdown that could cause leaks

- Maintain packaging compliance

What is the Poison Prevention Packaging Act?

The Poison Prevention Packaging Act (PPPA) was first implemented back in 1970 as a set of regulations regarding child resistance packaging. The PPPA requires that certain packaging be significantly difficult for children under five years of age to open, while still reasonably feasible for most adults to use properly.

Products that require PPPA-compliant packaging include:

- Chemical and cosmetic products

- Mouthwash products containing 3 grams or more of ethanol

- Medicinal drugs and dietary supplements

The PPPA includes accommodations for the elderly and those with disabilities, allowing manufacturers of non-prescription products to package one size of a regulated product in regular packaging. Manufacturers must offer the given product in additional sizes that are child resistant, as well as label the regularly packaged items with warning labels.

How Can Packaging Design Help Improve Poison Prevention?

To create safer products, PPPA-regulated items must be validated and tested for having child resistant designs. However, this is only one part of poison prevention.

While younger children are particularly susceptible to poison exposure, poisonings happen across all demographics. That is why designers must create packaging that is not just child-resistant, but also has other means of helping to prevent accidental poison exposure.

Other poison prevention considerations for packaging include:

Labels and Visual Design

Packaging is often made to grab a customer’s attention and push a brand. Similarly, the aesthetics and labels of a package can help to deter accidental poisoning, clearly warning users of the contents inside. This can also extend to helping create designs that can better give warnings and context for the visually impaired, like using braille labels.

Leak-Proof Closures

The closure or cap of a package can be a primary point of product leakage if not designed properly. If the cap height is too large, the cap will not be able to mate properly with the top of the bottle’s threaded neck. This will leave the liner unsealed. If the cap diameter and/or the thread diameter are too large, it can cause the threads to strip when closing the bottle and tightening the cap. Of course, if the cap is instead too small, then it won’t fit the bottle.

Essentially, anything that interferes with the mating of the cap to the rest of the package can cause leakage. Since this connection can become warped with use, having closures and packaging that better maintain their structural integrity over time is key to poison prevention.

Liners and Tamper Evidence

Choosing the right liner is critical to packaging design. Liners directly influence a user’s access to the product, with liner-less closures offering better seals for certain products.

If you use a liner, it can serve as a safety mechanism, provide evidence of tampering, and control the manner/rate users can dispense the products. Tamper evidence is important, as it can warn users that something has been put in or taken out of a package.

Online-Friendly Packaging

With the rapid growth of e-commerce platforms and Amazon fulfillment centers, packages are becoming less and less likely to wait around on store shelves until they are bought. This new change in delivery comes along with different packaging needs and requirements.

Special considerations include:

- Extreme temperatures and humidity

- Stacking, compression, and load shifting

- Conveyor belts and mishandling

- Roadway vibration

Better Packaging at MRP Solutions

Here at MRP, our team is committed to creating better packaging for the world’s leading industries. In addition to creating attractive packaging that meets all of your performance needs, Mold-Rite can help minimize the possibility of poison exposure with safety-enhanced packaging designs.

Contact us today to learn more about how the experts at MRP can help you create better, safer packaging.