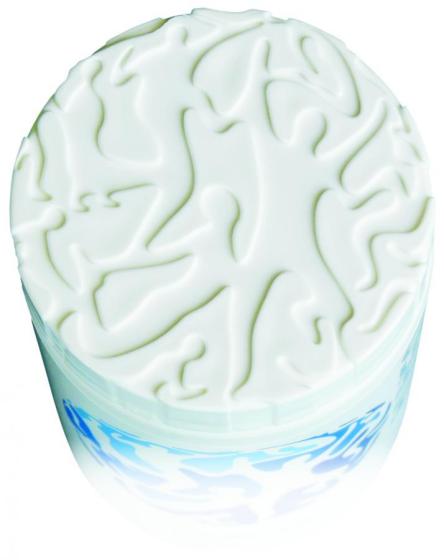

New Plastic Closures Feature Custom Logo and Finish

Package designers know that a container’s plastic closure, though perhaps small in size, can really make a big impact on customers and distributors. USANA Health Sciences of Salt Lake City understood this when it decided to develop a new brand logo and package for its line of vitamin and mineral supplements in early 2012. USANA partnered with several companies to complete the redesign, including MRP Solutions. The project was even featured in a recent edition of Packaging World magazine.

MRP was selected to develop the custom plastic closures because of its in-house tool-build capabilities and modular mold design capabilities. With over 1,200 molds in-house, the company can take a stock part and create a custom design by using existing manifold systems and cores, and then changing the cavity plate. At its three manufacturing facilities, the company operates 85 injection presses, ranging from 100 tons to 750 tons.

MRP was selected to develop the custom plastic closures because of its in-house tool-build capabilities and modular mold design capabilities. With over 1,200 molds in-house, the company can take a stock part and create a custom design by using existing manifold systems and cores, and then changing the cavity plate. At its three manufacturing facilities, the company operates 85 injection presses, ranging from 100 tons to 750 tons.

The solution for USANA involved putting horizontal lines on the side of the plastic closure so that it would release correctly from the mold during the injection-molding process and facilitate industry-standard production speeds. By keeping the closure depth at 0.05 in., manufacturing costs were also kept down.

By using the existing cores and manifold systems, Mold-Rite helped expedite the process and got the closures out to USANA in just 10 to 12 weeks. Mold-Rite created five cap sizes to match five container sizes, ranging from 75 to 400 cc, on a new KraussMaffei injection press.

“Overall, the response from our distributors has been very good. Customers are happy with the new look and have embraced the new identity,” said John Cordova, Executive Director of Brand Management for USANA.

To view more products from MRP Solutions, click below: